Service Manual.

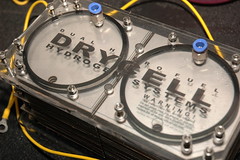

Step by step how to clean the Dry Cell Kits Generator. The generator need to be clean if : 1. The water inside the generator turn dark brown. 2. Amp meter show very minimum amp is use although after 1 hour running. 3. After 2000-3000km (304 S.Steel) or 40,000-50,000km (316L)

Please flush the water inside the reservoir and the generator first refill with fresh distilled water and new electolyte. If the amp is still low, then its time to clean up the internal surface of the generator.

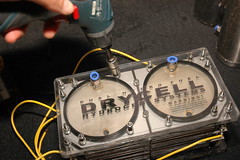

1. Disamble the generator by turning the screw anti-clockwise.

2. Make sure the outer layer is open straight flat up.

3. This is the inner part surface of the generator after running about 800km. This generator is 304 s.steel using a distill water. You can see the surfce is turn a little bit browninsh. Actually in this condition it does not need to be clean yet. Only if the surfce is turn into a dark brom colour.

4. Sometime the surface can be clean by hand. If it is hard to clean, get a brass wire mesh or sand paper to sand the surface.

5. When you disamble the units, make sure the rubber seal is kept in a clean water. This rubber seal must be stay wet. This is a special made rubber that can stand heat up to 400c. This rubber seal we use in this design is very durable. It can be expand in case of HHO explosion. So will not effected other parts of the generator.

6. A clean surface after cleaning.

7. Thightened back the scew clockwise but not too tight. Make sure the layer is flat.

8. Manually thightened the scew to get the precise space between layer.

9. Get a ruller and make sure the spacing is correct to the measurement below. Measured from the Outer transparent layer (As pictured) 1. 2HHO-33P8C (DCHHO0041) - 140mm 2. 2HHO-25P6C (DCHHO0031) - 105mm 3. 2HHO-17P4C (DCHHO0021) - 75mm 4. 2HHO-9P2C (DCHHO0011) - 50mm

Ready to install back to your vehicle. |